Energy Conservation has gained momentum in recent years. The increasing demand for energy efficiency has influenced the technical development of right construction methodology and usage of right products for façades and windows. Now a days advanced and technically superior innovative solutions are available which are cost effective and facilitate greener buildings with a low carbon footprints.

On an average depending upon the location in the world, it is observed that buildings consume more than 30 – 40 per cent of energy. In extreme cold and hot regions this consumption may go more than 40 per cent as well.

Windows and façades are few of the most important factors while considering the overall energy efficiency of a building. Therefore the requirement and selection of right construction methodology and right products is very important and it helps in achieving the overall performance. Special type of products in the form of sealants, foams and adhesives with better weather ability, durability and waterproofing properties are required to achieve this.

The use of sealants, adhesives and foams in building design, has given extra dimension with the increased durability of structures, better performance and preservation of the building’s environment and a reduction in material consumption for the construction of the façade and windows.

Concepts of EPB, NZEB and Passive House

The European concept of EPB (Energy Performance of buildings) to reduce CO2 gas emissions by 20 per cent, to reduce energy consumption by 20 per cent and to increase the share of renewable energy to 20 per cent (reference year: 1990), and NZEB (Net Zero Emission Building) has gained significant attention these years. The concept of nearly zero or very low amount of energy required should be adopted to a very significant extent by energy from renewable sources, including energy from renewable sources produced on-site or nearby. These stricter norms not only advocate the use of one form of energy, but pays significant attention on reduction in energy consumption.

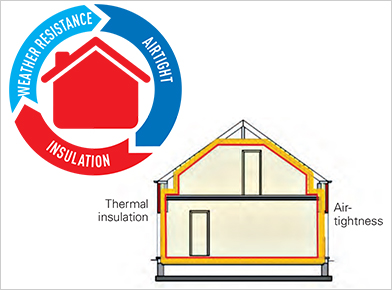

For translating these principle into building practice, it is of prime importance to take great care ensuring that the building envelope is very well insulated and airtight. Attention should also be paid to good compactness, orientation and of course, controlled ventilation. In the original concept, the ventilation ducts were also used for heating purposes; due to the absence of a classic ‘active’ heating system, this type of house was called a passive house. Meanwhile, even though other “heating aids” are being used, the basic criteria for a passive house have remained the same:

- 1-Net energy need for heating ≤15 kWh/m2 per

year - Airtightness n50-value ≤ 0.6 vol/h

- Temperature exceedance factor above 25°C ≤

5per cent

This translates into a building which has, in winter as well as summer, a very comfortable interior climate and requires only a minimum amount of heating. It is obvious that a passive house is the ideal way to achieve an NZEB as the limited energy need can easily be met by renewable energy.

Major Issues in Building/ Window Systems

Thermal Bridges

In many European countries, while calculating the energy performance, any thermal bridges (cold bridges) calculation in a building is taken into consideration. This is quite logical as poorly executed building knots may lead to large transmission losses resulting in an average heat loss of 5per cent (for an average house). Designers must therefore pay attention to joints, especially joints between various construction elements. Window-to-wall joints, for example, are important potential thermal bridges, which easily amount to 100 meters for an average house.

Many available Window System (SWS) can contribute to lowering heat loss, as thanks to the use of Flexifoam in the SWS details the, possibly pre-calculated, Ψ-value can be kept low and, as the case may be, below the limit imposed by prevailing EU legislation (e.g. 0.1 W/mK).

Joints

In comparison to other aspects of construction, joints are often not given the attention they require. Building joints need to be thoroughly planned and are necessary to compensate for the expansion and contraction of building materials or to create fitting tolerances. In practice, however, the result can be irregular joint dimensions or even unplanned joints. The sealing of joints can result in one of the following functions or a combination thereof

- Acoustics

- Airtightness

- Aesthetics

- Thermal insulation

- Fire protection

- Protection against burglary

- Protection against driving rain and humidity

Acoustics

For quite some time now, tightened requirements with regard to acoustics (NBN S 01-400-1) apply in many countries. But the saying “a chain is as strong as its weakest link” certainly applies to soundproofing. An elastic filling material or a combination of these materials is particularly suitable to reduce the transmission of sound. A reduction of air sound is expressed in a reduction index ‘R’.

Airtightness

In the context of airtightness not only refer to joints (planned), but also to seams and crevices, which are mostly undesired or irregular joints or interfaces. For products able to seal seams, crevices and joints, the current product standards contain none or very few specifications or requirements regarding airtightness. However, in European standard, EN12114, which describes a general testing method to measure the air permeability of building products (in laboratory conditions).

The result is a value indicating the leak flow per m or m2. For sealants and adhesives, it generally applies that there should be sufficient cohesion (the material does not tear) and adhesion (bonding) to guarantee the airtightness over a longer period. For sealants, the cohesion is linked to the movement capability of the product; the adhesion is strongly determined by the preparation and condition of the surface. In brief: selection of the correct product for the application, due care when applying the product and choosing a good quality product will always lead to the best results.

Aesthetics

Joints, and especially the correct finish of joints, can contribute to a smooth appearance, of the inside as well as the outside of a building or construction. Not only the texture, but also the colour of the sealant play an important role.

Thermal Insulation

A number of products, especially construction foams, score very well in terms of heat insulation. The lambda-value (λ) is used as indicator. In particular in wider joints, thermal bridges need to be avoided. The 3D correction factor in a joint between 2 insulating surfaces is called the psivalue (ψ). The minimum requirement in Belgium for window to wall interfaces is set at 0.10 W/mK.

Protection Against Fire

Joints and penetration seals are an important link in the finish of compartments. Compartmentalization forms an essential part of passive fire protection in buildings. The relevant standards are EN1366-3 for penetration seals and EN1366-4 for joints. Fire resistance is expressed in minutes; for joints and penetration seals mostly related to flame integrity and insulation.

Protection Against Burglary

For exterior joinery this characteristic is classified in accordance with EN1627 to EN1630. Elastic glazing sealants can certainly have advantages here and will also ensure better airtightness and water tightness of the window.

Resistance Against Driving Rain

These are, in fact, products which are not simply watertight, but can also keep water from entering when it is combined with an increased (wind) pressure. This pressure increases in proportion to the height of the building. For instance, at a building height of 50 m or more, this pressure may increase to 600Pa or more. As a primary barrier, these are mainly joint sealants suitable for use in facades and glazing, which also have good movement capability. They have been classified in accordance with the new CE marking (harmonised standard EN15651) or the EN ISO11600 standard: ‘F’ for façade, ‘G’ for glazing – 20per cent or 25per cent movement capability. As we are talking about outside applications, these products must also be UV resistant.

Vapour Control

Damp protection and vapour control is also an important issue for a healthy building. It can therefore be important to include the μ-value of a substance when sealing joints or even the Sd-value of a specific building material.

Conclusion

Windows, Doors & Facades are very important part of building, it is very important for architects & consultants to consider the use of energy efficient & sustainable products available in the market to achieve the best results in conserving the energy. In nut shell the Energy conserved is the Energy saved.

For further information on this subject applications,You can reach us at niten.patial@mccoysoudal.com

For further information on this subject applications,You can reach us at niten.patial@mccoysoudal.com