Covid had hit hard not only in India but the whole world. This Pandemic has affected most businesses. At the top of it, the prices are skyrocketing today. The price of PVC increased is 120 %, Steel from Rs 72 to Nearly Rs 100; other materials like Zinc, Aluminium increased by 40%; fuel at its top at Rs 110; container charges from China today $10,000, which was $1800 a year back. So the end-user which is the ultimate buyer has to shell out nearly 30% more and it is not stopping now.

Well, as far as demand is concerned it is definitely back, rather than increasing. India is a developing country and a growing economy. So COVID can give short-term pain but no one can stop India’s gain.

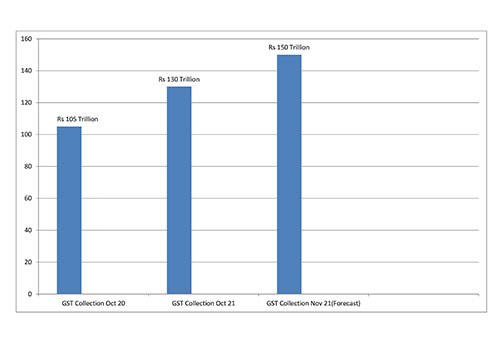

The GDP collection on October 21 was at a whopping Rs 1.3 trillion from 1.05 trillion last October (2020) which itself says around 30 % of growth. The construction industry has given 20% GDP growth in the last quarter. BSE is at its best at 60,000. So Indian economy is gaining momentum. Whatever loss has been incurred in the fenestration Industry during the lockdown in 2020 and 2021, it is already on the path of recovery and the requirement today is at its peak.

Market Size Of Fenestration Hardware – Potential

The total fenestration Industry stands at Rs 30,0000 Cr and As far as uPVC is concerned it should be nearly at Rs 3500 Cr and consumption of Profile is approximately 80,000 T of profiles. We did not see growth from 2019 -20 to 2020 -21 but at the end of 21-22, we are expecting 10-15 % of growth for the industry.

Hardware plays a major role in doors and windows. It is not only important for smooth operation but also the aesthetic looks. Hardware gives you proper sealing, ventilation, waterproofing, multi-locking, etc. So it is very important to choose the right hardware not only in terms of quality but also according to application. Here are some important criteria to be followed:

1. Selection of Hardware:

This is one of the major criteria that how and which hardware to be selected for the particular window /Doors. There are numerous profile sections, and hardware can be different for the profiles. The wrong selection of hardware can lead to failure In operating Windows. So it has to be selected according to fitment on that particular profile.

There are instances where the buyer of Windows has selected an expensive profile but because of the wrong selection of hardware, the window could not be operated well. So the whole purpose is defeated.

2. Quality of Hardware:

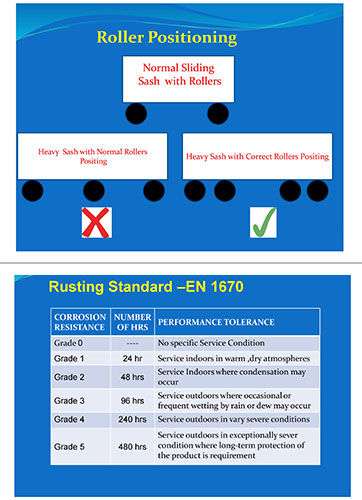

It is a very important criterion. Before Selecting the hardware one needs to check the certification from the manufacturers. The major ones are the operating cycle test which should be 25000 cycles whether it is multi-locks, handles, rollers, etc. Further, there are different weather conditions in countries – so a Salt spray check is a very important criterion. It should pass at least Gr3 ( 240 hrs) and the best could be Gr5 (480 hrs). It is recommended to use SS 304 in Coastal Areas and sometimes even SS 316 if the site is Just near the beach. Please refer to the below chart.

3. Application/Fitment of Hardware:

Once we select appropriate hardware with the best quality, then comes the proper fitment on the window/ doors. Workers have to be skilled and trained for that. They should use proper Jigs for the fitment, the position of rollers to be taken care of, the size of the multipoint lock should be as per the height of windows, etc.

Once we follow the above three criteria then we can make perfect windows/doors. In the end, I would like to say that with Covid cases dipping and vaccination increasing the future for the hardware industry is very promising. It is the right time to invest, so companies can make a good profit in the next decade.