Tell us about your practice and design approach?

NORR is a multi-disciplinary Architecture & Engineering practice with offices across North America, the UK, and the UAE. NORR has been established in the UAE for 33 years, with a significant portfolio of work across the Middle East. Championing the convergence of art and science, our approach to design is truly collaborative, combining the experience and specialist knowledge of our architects and engineers, in combination with external specialist designers and clients to deliver comprehensive and holistic solutions to design projects. In the role of Lead Consultant, from design inception to completion on-site, our team is carefully selected to ensure the best possible outcome of each project, combining local knowledge with global expertise.

Could you please tell us about your journey in the field? How did you think of becoming an architect? What do you enjoy most about your profession?

I have always been interested in design, in the wider sense. I studied design at school, and seriously considered Product Design as the way forward. My first job was on an Orchid Farm in New Zealand, designing and building systems to simplify and automate the picking of delicate blooms. An internship at a small Architectural Practice in England, and with a small contracting company in Osaka, Japan, cemented my desire to further my interest in design in the field of architecture.

Following graduation from the University of Dundee, I worked in Edinburgh for 15 years, working on hospitality, commercial and retail developments across Scotland and the North East, before relocating to Dubai in 2012. Over the past 10 years, I have led NORR’s multi-disciplinary teams on a variety of developments in the hospitality, residential and commercial sectors with NORR.

Please talk about your projects featuring very innovative and different kinds of façade and fenestration designs.

Ciel Tower. Slated to be the tallest hotel in the world on completion in 2024, is currently under construction in Dubai Marina, for The First Group. The tower has a curved plan and tapered section, resulting in a complex double-curved façade profile.

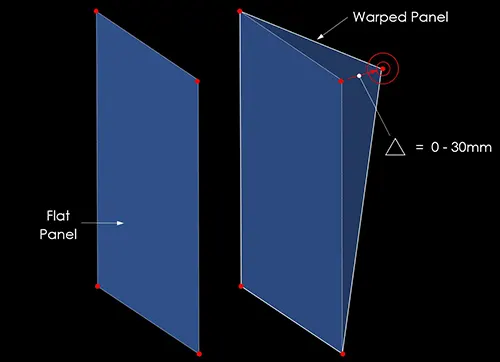

Working closely with our façade engineering consultant, AESG, we chose to use ‘cold bending’ technology to achieve the subtle curve required in each unitised glass panel. The technology is simple, in principle. One corner of the panel can be bent away from the flat plane, up to 30mm. The more extreme the bend, the more stress put on the glass, resulting in higher costs, and a greater risk of failure.

An iterative design process using the parametric software Grasshopper was carried out to achieve two goals:

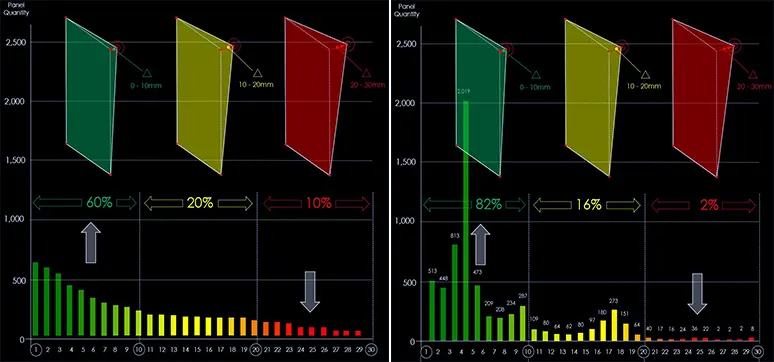

- A achieve a panelisation layout across the tower avoiding oversized and under-sized panels, whilst achieving an aesthetic uniformity. A total of 6,200 panels.

- Rationalise the extent of cold-bending required for constructability and cost-efficiency.

The building does not, fundamentally, appear any different from the design vision. However, the detailed collaboration between architecture and engineering has resulted in a clean, efficient solution, complemented by cold-bending technology.

The study required minor refinement of the floor-plate slab edge line on every floor, combined with panelisation optimisation to significantly reduce the volume of panels bent to the extremes, and the majority of panels now bending to 100mm or less. From a baseline design requiring approximately 30% of panels requiring to be bent to 10 mm or more, the resultant design has just 18% of panels requiring a bend of 10mm or more, with the remaining 82% of panels bending at 10mm or less.

How do you go about choosing materials for façade and cladding?

Material selection is the result of a number of factors. Materials are selected considering the proposed façade systems, to combine the aesthetic, long-term durability, maintenance regime, value, and cost. With a long-term presence in the UAE, the selection of locally-sourced products and technologies from a fast-maturing local market improves the environmental impact of our choices, reducing ‘material miles’ wherever possible. The use of new materials and technologies is not a matter of fashion, but the careful consideration of emerging technologies, providing ever-increasing technical performance.

What do you think is the role of the façade in the sustainability enhancement of a building?

Sustainability does, of course, require a holistic approach to design, with contributions from all disciplines, from the macro – urban planning, infrastructure, and community – through to the coordinated approach and systems that develop the ‘building as a machine for living in. The façade is the first line of defence. A shield between the internal and external environments.

It is through exploring the visual and physical permeability of façades that creates opportunities to improve the performance of a building, through both active and passive sustainability measures, to improve the internal environment in terms of user experience, and energy levels required to sustain them. As an example, U-values and Shading coefficients of glazing systems are considered in parallel with light transmittance and reflectance values, to achieve an optimum balance between thermal performance, and natural light quality for the building occupants.

The thermal performance of all aspects of the façade is critical to achieving energy efficiency, avoiding the traditional warm bridging weak points at slab edges, balconies and projections.

How do you see the architectural industry in the Middle East? What are the challenges and opportunities?

The local and regional design codes are improving year on year. The Middle East, and the UAE in particular, has the ability to catch up with international standards and surpass them with time. I believe a lot can be learned from regions faced with extremely cold climates – Scandinavia for example. The challenges of dealing with extreme temperatures, whether hot or cold, are largely the same. Fully thermally broken systems and triple glazing are the norms in many countries, and I think we should expect them to make an appearance here, along with more sophisticated external wall build-ups, moving away from insulated masonry block and their inherent reliance on workmanship.

The UAE has seen recent experimentation in 3D-printed systems and buildings on a small scale. The expansion of modular construction, 3D printing, and automated installation techniques have the opportunity to increase construction quality and speed, whilst reducing reliance on low-skilled labour.

Please tell us about a few of your favourite projects you were involved in. Please share their façade & fenestration design details.

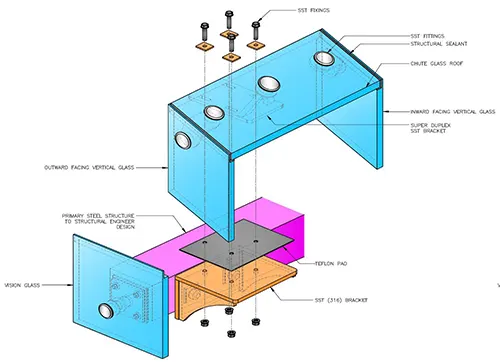

One of our more challenging façade designs offered the opportunity to push the boundaries of structural glazing. The Sky Slide at The Address Skyview is an ‘all glass’ slide, providing an adrenaline-pumping ride from Level 53 to Level 52 of the Address Skyview in Dubai.

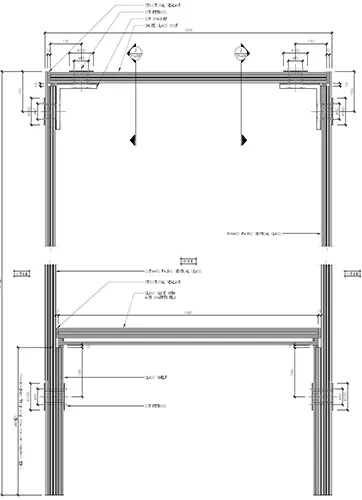

An international team of designers, comprising NORR, Koltay Façades, and M.Ludvik Engineering in New York, conceived a strategy using the latest available glass technology.

A mock-up of the slide was built and tested by users of every height and weight. The slide angle, run-out length, and surface treatment were adjusted to validate the design, prior to construction. Multi-laminated glass panels, built from individual sheets in excess of 14m sourced from Germany were created and held together using the structural sealant. Staggered lamination in the sidewalls creates a physical seat for the sliding plane. The ‘square tube’ slide structure provides a fully air conditioned environment, extending the internal environment in free space, 220m above the ground. The tube is supported solely at each end, through bespoke designed and engineered stainless steel fittings, designed to accept the thermal and structural movement of the system.

Testing to failure of the system build-up, combined with extensive factory load-testing validated the design calculations, and inherent safety factor built into the design.

What are the changes you see in façade design over the years?

There has been a significant increase in the range of technologies available to designers. Whilst the standard systems continue to evolve by ever decreasing increments – improved energy efficiency, insulation values, and specialist coatings – new opportunities are evolving through prototypes and into the market. The size, in terms of length, overall area, and performance, provided by glass manufacturers is increasing significantly, as described in the Skyview slide, enabling statement façades.

Modular construction gives designers the opportunity to design a comprehensive façade, incorporating structure, solid panels, and glazing, in a myriad of materials, fully constructed in factory conditions. Modular construction has moved on from bathroom pods to including full hotel rooms, apartments, and villas. ‘Plug & Play’ MEP systems and connecting structure results in fast, safe, construction, with modular construction starting to make its presence felt in mid to high rise development.

Technical fabrics, like ETFE, are now commonplace with pressure-balanced cells to better respond to significant temperature gradients. Carbon fibre is increasingly an option for mullions, with a moulding approach that allows more complex forms than the traditionally extruded aluminium systems, both for aesthetics, and to pick up structural load paths. Active solar shading systems, responding automatically to external weather conditions, reduce solar gain and increase user comfort. 3D printing offers the opportunity to create bespoke façade elements with little to no material wastage, and avoid the cost penalty of non-repetitive elements constructed more traditionally.

Please explain the role of design systems in firesafe buildings?

True fire engineering is a holistic process, coordinating all aspects of a building, both passive and active. A passive response incorporates building layout and configuration, escape routes and stairs, and sound material selection. Active systems, such as fire alarms, sprinklers, suppression systems & evacuation protocols, complement the passive design approach to provide a comprehensively fire-safe building. The thoughtful approach to the passive aspects of design has the opportunity to mitigate the complexity of active systems, and to provide a safe, balanced response to the risk of fire.

One piece of advice you would like to give to aspiring architects?

An architect’s training should encompass far more than the content of a degree course. One piece of advice? Get your hands dirty! Spend time on site. Mix concrete, lay bricks, and do some joinery at home. Labour for a skilled craftsman. An understanding of what the lines on the paper really mean will vastly improve your understanding of how things go together, and the constraints and opportunities that different materials offer.